Ramco Steels is committed to developing, manufacturing, delivering and servicing quality products. Our goal is to continuously improve our products and services in order to satisfy the needs of our customers – before, during and after sales.

In each of our product category, our quality is amongst the best in the world. We use the best quality of raw materials that are tested and subjected to stringent standards as per required specifications. SPC analysis is carried out to check all critical parameters during production. Every batch of finished product undergoes strict down the line process control monitoring which guarantees superior ISO 9001:2015 Certified quality products. As a result, Ramco is synonymous with technology, quality and service.

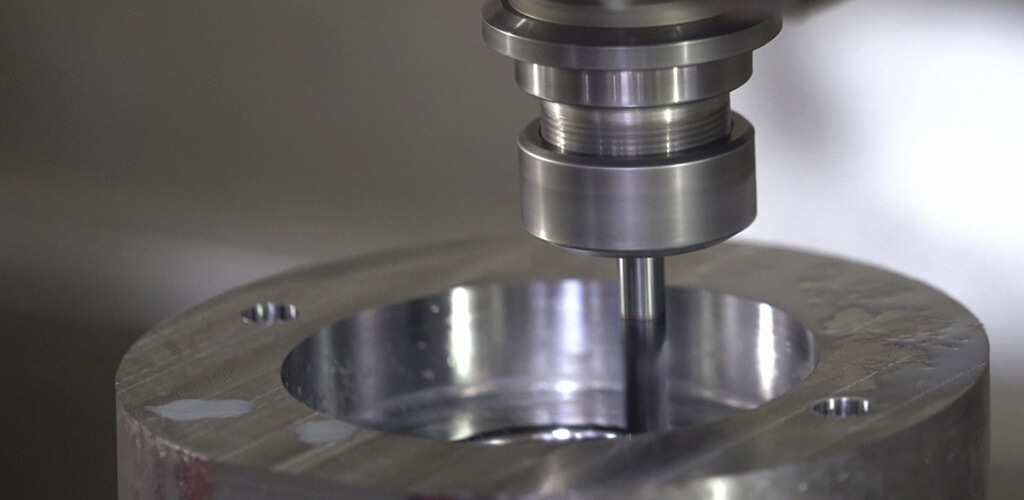

Our machine shop has witnessed explosive growth over the last few years with the addition of 250+ CNC Lathes (6″, 8″ & 10″) and 100+ Vertical/Horizontal Machining Centres. To complement the machining capabilities, we have in-place, several 3D-CMM equipments & Contour Measuring Machines, to reduce the first-off part approval time, CNC initial set-up time & maintain strict quality assurance standards.

We are an IATF 16949:2016 & ISO 9001:2015 Certified company with the latest

certification under issue.

| Machine Model | Nos |

|---|---|

| Zeiss 3D Co-ordinate Measuring Machine | 5 |

| Renishaw Online Probing System | 46 |

| Mitutoyo Contracer CV-3100 | 5 |

| Hommel / Mitutoyo Roughness Testers | 5 |

| Mitutoyo Height Gauges / Vernier Calipers / Micrometers / Others | 500+ |