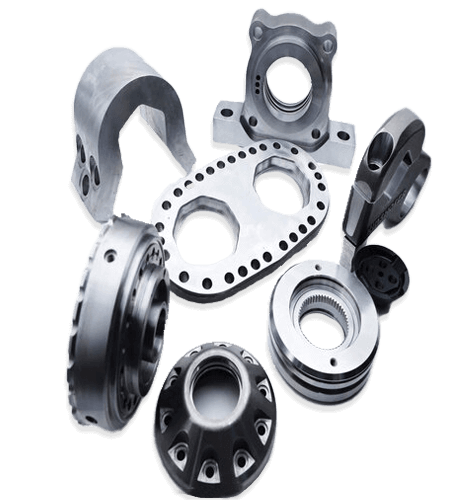

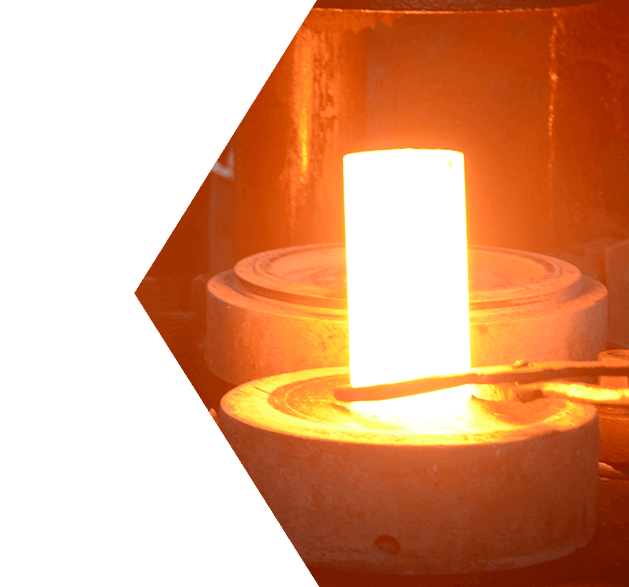

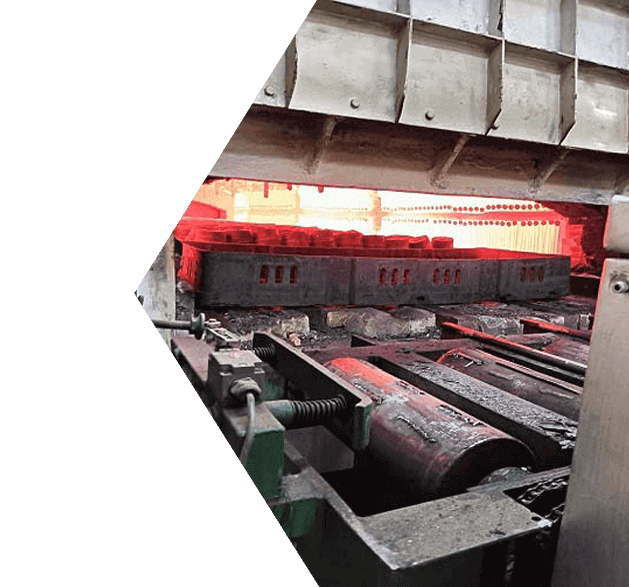

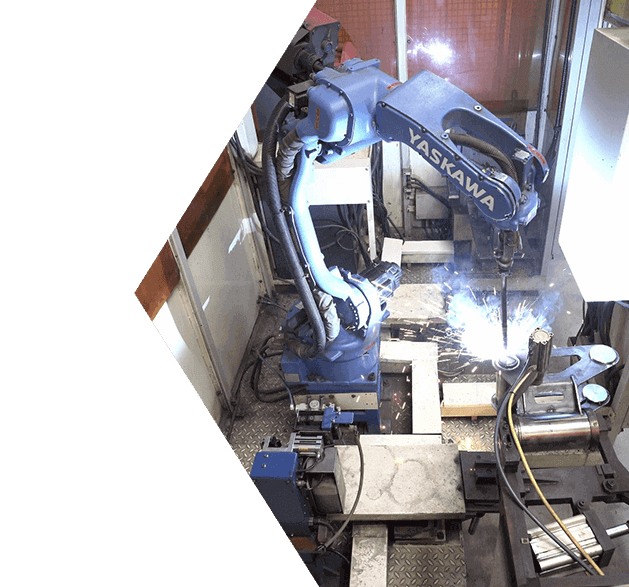

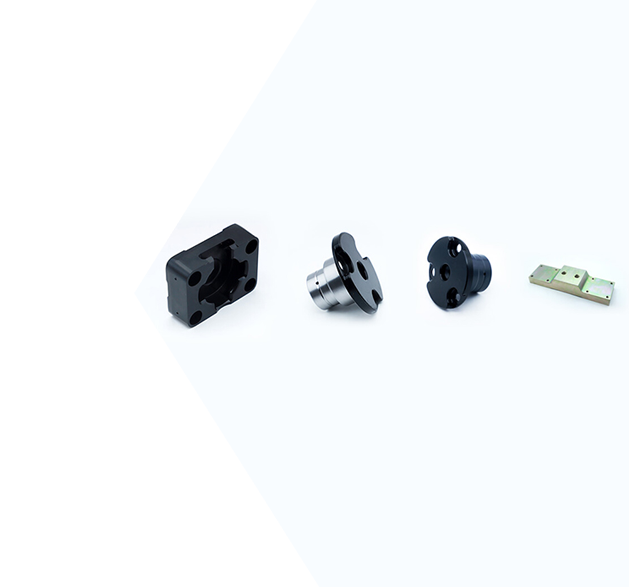

Ramco Steels Pvt. Ltd. is an industry leader in the manufacture of forged and CNC machined components for the Indian and global market. Established in 1994, Ramco has carved a name for itself with its vast range of high-quality customized parts, engineering competence, prompt lead times and competitive pricing.

Read More

At Ramco Steels, We revel being able to anticipate Our Customer's need and apply a flexible approach to deliver result with precision as well as timelines.

We take pride in the fact that our esteemed customer inculde some of the biggest names across continents worldwide.

Frieght Term Offered