Ramco can produce hot forged parts from 50 grams to

45 kilograms.

This is done using mechanical hot forging presses and

electric screw presses ranging from 300 to 2500 tons,

ring rolling equipment and 3.3 ton belt drop hammers.

Induction billet heating and forging simulation are essential

technologies used for optimising the forging process.

Ramco Steels also has post machining heat treatment

capabilities like induction hardening and tempering soft

carburizing to cater to customer requirements. Operations

like case hardening, gas nitriding and plasma nitriding

are outsourced under strict quality checks to well established vendors.

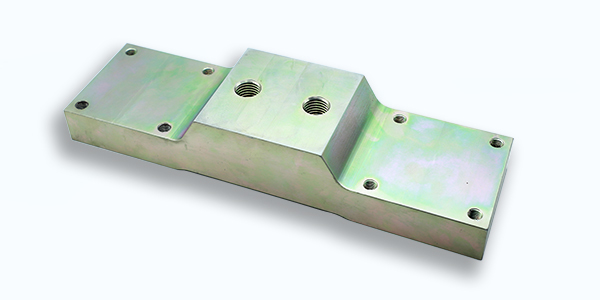

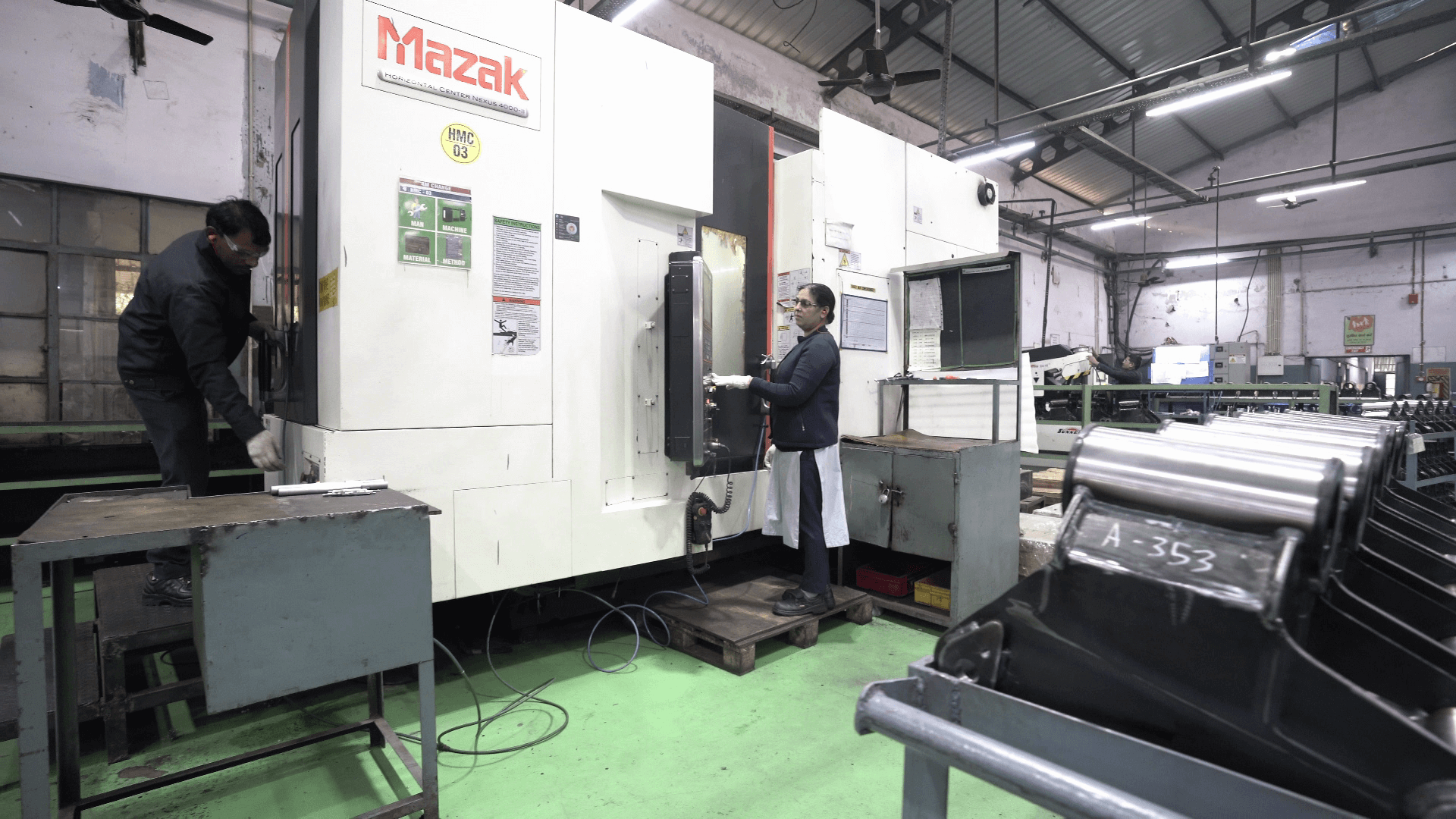

More than 300 CNC Turning & Milling machines

process forgings, castings,burnt plates, welded

assemblies and bar-stock pieces, weighing from 50

grams up to 95 kilograms.

Most of the vertical and horizontal milling machines

are equipped with fourth and fifth axis rotary tables

as well as Renishaw online probing systems. In addition,

Ramco has cylindrical grinding, spline and keyway

broaching,vertical honing, Deep hole drilling, lapping,

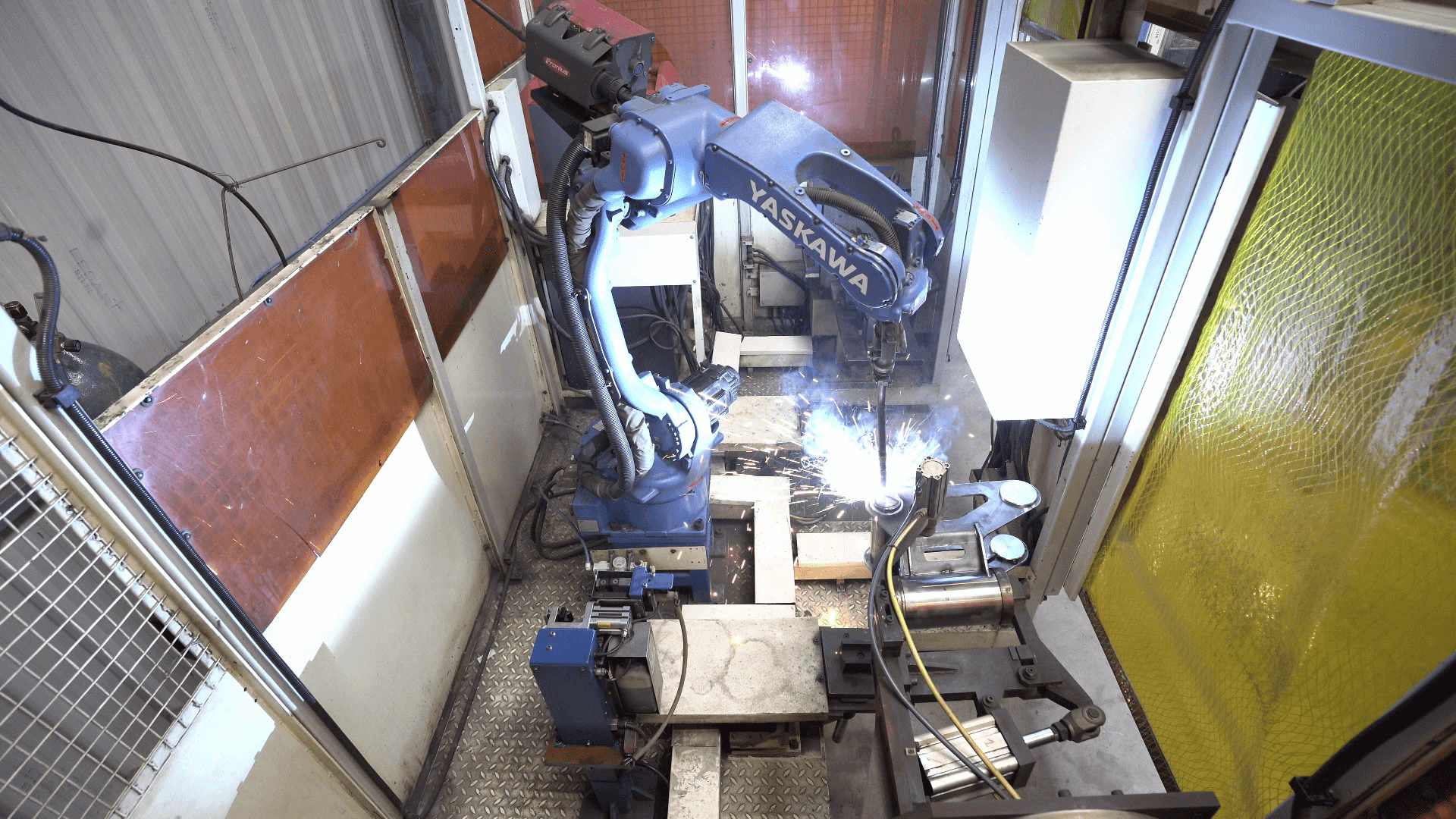

vibratory polishing and Robotic MIG Welding capabilities.

Ramco can robotically weld fabrications using child parts

such as forgings, castings, burnt plates and bar-stock pieces.

Treatment

Ramco also offers various surface treatments like

electro galvanizing, zinc nickel plating KTL coating

and painting through approved vendors.